Unlock the Amazing Power of Fixed Inductors!

Have you ever wondered how certain electronic components help in controlling the flow of electric current in circuits? One of the most important components in this regard is the fixed inductor. Fixed inductors are used in a wide range of electronic applications and are one of the most versatile components in a circuit. In this article, we will explore in detail the various properties of a fixed inductor, how it works, the types of fixed inductors, the different applications, and how to design, select, and troubleshoot fixed inductors.

What is a Fixed Inductor?

A fixed inductor is a passive electronic component that stores energy in the form of a magnetic field when a current passes through it. It works on Faraday’s law of induction, which states that a changing current will induce a voltage across any circuit. Fixed inductors are used in a wide range of applications, including filters, signal processing, and power conversion. They are also used in power supplies, automotive electronics, and radios.

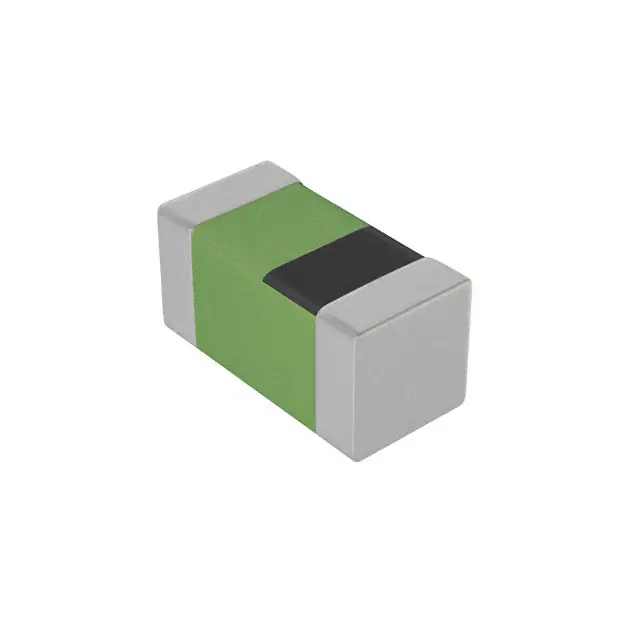

Fixed inductors are available in a variety of shapes and sizes. The most common type is the axial lead inductor, which consists of a coil of wire wrapped around a ferromagnetic core. The other type is the surface-mount inductor, which is a smaller version of the axial lead inductor. The core of a surface-mount inductor is usually composed of a ferrite material.

Fixed inductors can be classified according to their inductance, which is measured in henries. Inductance is a measure of the amount of energy stored in the magnetic field of the inductor. The higher the inductance, the more energy is stored in the inductor.

How Does an Inductor Work?

An inductor works by storing energy in the form of a magnetic field when a current passes through it. When a current passes through an inductor, it induces a voltage across the inductor. This voltage is known as the inductance voltage. The inductance voltage is proportional to the rate of change of the current, which is known as the inductance current.

The inductance current is dependent on the inductor’s inductance, which is a measure of how much energy is stored in the magnetic field of the inductor. The higher the inductance, the more energy is stored in the magnetic field of the inductor.

The inductance voltage is also dependent on the inductance current. As the inductance current increases, the inductance voltage also increases. This increase in voltage is known as inductance voltage drop.

The inductance voltage drop is also dependent on the frequency of the current passing through the inductor. At higher frequencies, the inductance voltage drop is greater. This is because the rate of change of the current is greater, which causes the inductance voltage to drop more.

Types of Fixed Inductors

Fixed inductors can be classified according to their construction and design. The most common types of fixed inductors are axial lead inductors, surface-mount inductors, and ceramic inductors.

Axial lead inductors are the most common type of fixed inductor and are composed of a coil of wire wrapped around a ferromagnetic core. This type of inductor is available in a variety of shapes and sizes and is used in a wide range of applications.

Surface-mount inductors are a smaller version of axial lead inductors and are composed of a ferrite material. They are used in high-frequency circuits, such as radio receivers and transmitters.

Ceramic inductors are composed of a ceramic material and are used in high-frequency applications. They are used in circuits that require high inductance values and high current ratings.

Benefits of Fixed Inductors

Fixed inductors have a number of benefits when compared to other types of inductors. They are cost-effective, reliable, and have a wide range of applications.

One of the main benefits of fixed inductors is their cost-effectiveness. They are relatively inexpensive compared to other types of inductors and can be used in a wide range of applications.

Another benefit of fixed inductors is their reliability. They are designed to be durable and can withstand harsh environments. This makes them ideal for use in circuits that require high reliability.

Finally, fixed inductors have a wide range of applications. They can be used in filters, signal processing, and power conversion. They are also used in power supplies, automotive electronics, and radios.

Applications of Fixed Inductors

Fixed inductors are used in a wide range of applications, including filters, signal processing, and power conversion. They are also used in power supplies, automotive electronics, and radios.

In filters, fixed inductors are used to reduce noise and interference in a circuit. They are also used in signal processing applications, such as amplifiers and receivers.

In power conversion applications, fixed inductors are used to convert AC to DC. They are also used in power supplies to regulate the voltage and current.

In automotive electronics, fixed inductors are used to control the flow of electric current. They are also used in radios to convert the radio signal into an audio signal.

Designing Fixed Inductors

When designing a fixed inductor, it is important to consider the inductance, current rating, and temperature rating. The inductance of the inductor is the most important factor, as it determines the amount of energy stored in the magnetic field.

The current rating of the inductor is also important, as it determines the maximum amount of current that can be passed through the inductor. The temperature rating of the inductor determines the maximum temperature at which the inductor can operate.

Once the inductance, current rating, and temperature rating are determined, the next step is to select the material for the inductor. The most common materials used for fixed inductors are ferrite, iron-powder, and air-core.

Selecting the Right Fixed Inductor

When selecting a fixed inductor, it is important to consider the inductance, current rating, and temperature rating. It is also important to select the right material for the inductor.

The inductance of the inductor is the most important factor, as it determines the amount of energy stored in the magnetic field. The current rating of the inductor is also important, as it determines the maximum amount of current that can be passed through the inductor. The temperature rating of the inductor determines the maximum temperature at which the inductor can operate.

The material of the inductor is also important, as different materials have different properties. Ferrite and iron-powder inductors are the most common types of fixed inductors, while air-core inductors are used for high-frequency applications.

Fixed Inductor Troubleshooting

When troubleshooting a fixed inductor, it is important to check for any signs of damage, such as cracks or corrosion. It is also important to check for any loose connections or poor soldering.

If any of these issues are present, it is important to replace the inductor. It is also important to check the inductance of the inductor to ensure it is within the specified range.

It is also important to check the current rating of the inductor to ensure it is capable of handling the amount of current being used in the circuit. Finally, it is important to check the temperature rating of the inductor to ensure it is capable of operating at the required temperature.

Fixed Inductor Testing

Once a fixed inductor is installed, it is important to test it to ensure it is working correctly. One of the most common tests is the inductance test, which measures the inductance of the inductor.

The inductance test is performed by connecting a signal generator to the inductor and measuring the change in inductance as the frequency of the signal generator is increased. This test is used to ensure the inductance of the inductor is within the specified range.

The current rating of the inductor can also be tested by connecting a voltage source to the inductor and measuring the amount of current that is drawn. This test is used to ensure the inductor is capable of handling the amount of current being used in the circuit.

Finally, the temperature rating of the inductor can be tested by measuring the temperature of the inductor as the current is increased. This test is used to ensure the inductor is capable of operating at the required temperature.

Conclusion

Fixed inductors are one of the most versatile components in a circuit and are used in a wide range of applications. They are cost-effective, reliable, and have a wide range of applications.

When designing a fixed inductor, it is important to consider the inductance, current rating, and temperature rating. It is also important to select the right material for the inductor.

When troubleshooting a fixed inductor, it is important to check for any signs of damage, such as cracks or corrosion, and any loose connections or poor soldering.

Finally, once a fixed inductor is installed, it is important to test it to ensure it is working correctly. The inductance, current rating, and temperature rating can all be tested to ensure the inductor is capable of handling the required current and operating at the required temperature.

By understanding the properties of a fixed inductor and how it works, you can unlock the amazing power of fixed inductors and use them in a wide range of applications.